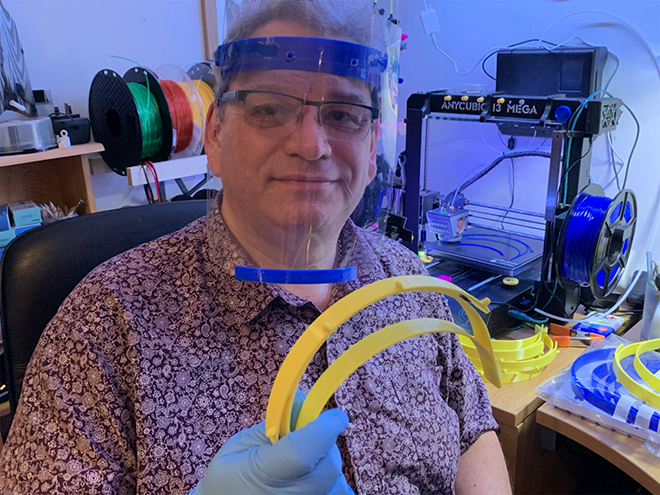

MEET IT manager Duane Litchfield, who is using the current lockdown to produce vital personal protective equipment for key workers.

Mr Litchfield, who works at chartered accountants Foxley Kingham in Luton, is producing face shields at home in Milton Keynes using a 3D printer.

He is printing round the clock and the shields he produces are dispatched to a central distribution point where they will be assembled with the elastic fastenings and sent to the hospitals with a shortage.

Each mask takes more than two hours hours to print so Mr Litchfield has been combining the printing of masks with his IT work for Foxley Kingham with the company’s support.

Foxley Kingham director Zeeshan Hussain said: “We are delighted that Duane is helping efforts to keep the frontline NHS workers safe during the COVID-19 pandemic. He is an innovative person and we’re proud of his work to support this great initiative.”

Mr Litchfield uses PETG plastic to print the masks via a market-leading Prusa printer that meets the strict key guidelines to adhere to regarding safety and hygiene.

The material can be sterilised which means the masks can be used repeatedly. Once he has a batch of shields ready, he contacts distributer DPD who are collecting 3D Crowd masks free of charge to help the initiative.

3D Crowd UK, which has been distributing more than 39,000 face shields a week to NHS trusts around the UK, is a central point for the shields to be assembled. From there the organisation manages the distribution of the finished shields to NHS departments.

Mr Litchfield said: “I usually use my 3D printer to make little Squirrel and Groot figures for my granddaughters to play with, it’s great to be able make a contribution to help keep the amazing NHS workers safe.”

by ANDREW GIBBS e: news@businessmk.co.uk

Donations can be made to help the logistics at 3D Crowd here.